Immersion gold uses the method of chemical deposition, through the chemical redox reaction method to generate a layer of plating, generally thicker, is a chemical nickel gold gold layer deposition method, can achieve a thicker layer of gold.

Gold plating uses the principle of electrolysis, also called electroplating method. Most of the other metal surface treatment is also used is the electroplating method.

In the actual product application, 90% of the gold plate is immersed gold plate, because the poor weldability of the gold-plated plate is his fatal flaw, but also lead to many companies to give up the gold-plated manufacture is the direct cause.

| Property | Appearance | Weldability | Signal transmission | Quality |

| Gold-plated | Golden with white | Simple Sometimes poor welding | The skin effect is not conducive to the transmission ofhigh-frequency signals | The welding resistance is not strong |

| Immersion Gold PCB | Golden | Very good | No effect on signal transmission | Strong welding resistance |

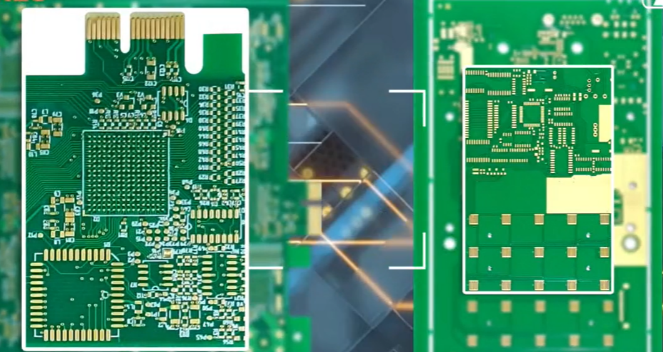

The Main Difference between Gold-Plated PCB and Immersion Gold PCB

Immersion gold manufacture in the printed circuit surface deposition of color stability, good brightness, flat plating, good solderability of nickel-gold plating. Can be basically divided into four stages: pre-treatment (degreasing, micro-etching, activation, after dipping), immersion nickel, immersion gold, post-treatment (waste gold washing, DI washing, drying). The thickness of gold immersion is between 0.025-0.1um.

Gold used in circuit board surface treatment, because of the strong conductivity of gold, good oxidation resistance, long life, general applications such as keypad, gold finger boards, etc., and gold-plated boards and gold-immersed boards the most fundamental difference is that the gold-plated is hard gold, more wear-resistant, while gold-immersed is a soft gold is less wear-resistant.