Multilayer aluminum substrate for automobiles is a circuit board using aluminum as the substrate, which is specially designed for automotive electronic equipment and has excellent thermal conductivity and mechanical strength.

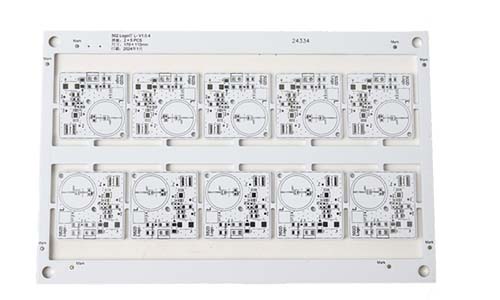

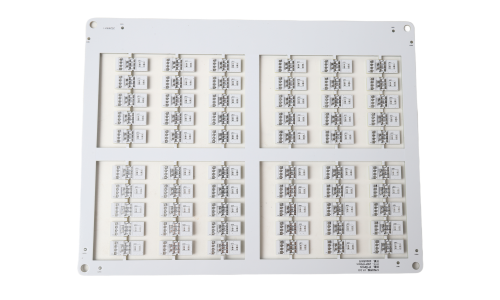

Aluminium Based Circuit Board Multilayer PCB Product Introduction

|

|

1. Product Overview

Multilayer aluminum substrate for automobiles is a circuit board using aluminum as the substrate, which is specially designed for automotive electronic equipment and has excellent thermal conductivity and mechanical strength. Due to its excellent heat dissipation capacity and lightweight characteristics, aluminum substrates have been widely used in automotive electronic systems, especially in the fields of LED lighting, power modules and high-frequency communication equipment.

2. Product Features

Excellent heat dissipation performance:

Aluminum substrates have good thermal conductivity, which can effectively dissipate the heat generated by electronic components during operation, reduce temperature, and improve the reliability and life of equipment.

Lightweight design:

Compared with traditional FR-4 substrates, aluminum substrates are lighter, which helps to reduce the overall weight of the car and improve fuel efficiency and endurance.

High strength and durability:

Aluminum substrates have high mechanical strength and impact resistance, which can meet the needs of automobiles in various harsh environments.

Good electromagnetic shielding:

Aluminum substrates can effectively shield electromagnetic interference (EMI) and improve the stability and reliability of automotive electronic systems.

Multi-layer structure:

Support multi-layer design, meet the needs of high-density integration, and are suitable for the wiring of complex circuits.

Surface treatment selection:

Provide a variety of surface treatment methods, such as spraying, anodizing, gold plating, etc., to meet the requirements of different applications.

3. Application Fields

LED lighting system: used for automotive interior and exterior lighting, instrument panel backlight, etc.

Power electronic module: widely used in the drive system of electric vehicles and hybrid vehicles.

Sensor and control module: used for automotive sensors, control units and other electronic devices.

In-vehicle communication equipment: supports in-vehicle wireless communication and navigation systems.

4.Technical Specifications

| Base material | aluminum alloy | Operating temperature | -40°C to +125°C |

| Number of layers | 2 layers | Surface treatment | lead-free spraying |

| Thickness | 2.0mm, tolerance plus or minus 0.15MM | Copper thickness | 1oz |

5. Production Process

1. Design verification: Use professional PCB design software for circuit design and thermal analysis.

2. Material procurement: Select aluminum alloys and insulating materials that meet industry standards.

3. Aluminum substrate manufacturing: The manufacturing of aluminum substrates is completed through processes such as stamping, etching, drilling and copper plating.

4. Assembly and testing: Soldering, assembly and functional testing of components to ensure product quality.

5. Quality control: Strictly follow ISO9001 and other quality management systems for production and inspection.

|

|

6. Customer Service

Technical support: Provide design consultation and technical support to help customers optimize product design.

After-sales service: Provide complete after-sales service to ensure customer satisfaction.

7. Summary

Multi-layer aluminum substrates for automobiles have become an indispensable and important part of modern automotive electronic systems due to their superior heat dissipation performance, lightweight characteristics and high reliability. We are committed to providing customers with high-quality aluminum substrate products and services to help the automotive industry's intelligent and electrified process.

FAQ

Q:Common problems of double-sided aluminum substrates such as: Insufficient thermal conductivity?

A: During the production process, if the thermal conductivity of the aluminum substrate is not strictly ensured according to customer requirements, it will affect its performance. This is usually tested by ASTM D5470 test.

Q: Insufficient peel strength?

A: The peel strength of the aluminum substrate is insufficient, which is consistent with the IPC test method of CCL, indicating that the aluminum substrate has problems in bonding.

Q: Poor heat resistance?

A: The heat resistance of the aluminum substrate is poor, which may be caused by inappropriate material properties or problems in the production process.

Q: Voltage resistance problem?

A: The aluminum substrate performs poorly in the voltage resistance test, and problems may be exposed in both DC and AC tests.

Q: The thickness of the dielectric layer is too large?

A: The gold image microscope test shows that the thickness of the dielectric layer is too large, which is also one of the common problems of aluminum substrates.

Q: How long is the general delivery time?

A: The delivery time for samples is generally 7 days, and the delivery time for batches is: 2Week.