Double-sided high temperature resistant flexible gold finger PCB is a specially designed printed circuit board that combines the flexibility and high temperature tolerance of flexible PCB and is widely used in electronic devices, connectors and high-performance circuits.

Temperature Resistance Flexible PCB Product Introduction

1.Product Overview

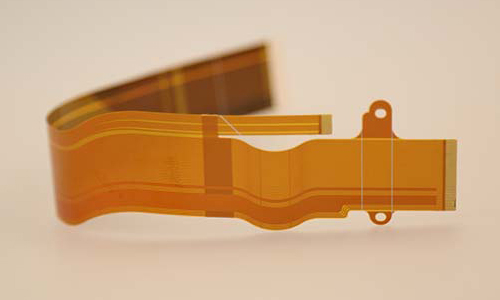

Double-sided high temperature resistant flexible gold finger PCB is a specially designed printed circuit board that combines the flexibility and high temperature tolerance of flexible PCB and is widely used in electronic devices, connectors and high-performance circuits. The gold finger part is usually used for connection and plugging to ensure reliable electrical connection.

2.Main Features

Double-sided design:

With double-sided circuit layout, it can realize more circuit functions in a limited space and improve the flexibility and density of the design.

High temperature resistant materials:

Adopt high temperature resistant materials (such as PI or PTFE), which can work stably in high temperature environment, suitable for high temperature welding and harsh working conditions.

Flexible characteristics:

Flexible PCB can be bent, folded and curled to adapt to various complex space layouts, especially suitable for miniaturized and lightweight electronic devices.

Gold finger design:

The gold finger part has been specially treated with excellent conductivity and wear resistance to ensure reliable connection during frequent plugging and unplugging.

Good electrical performance:

Adopt high-quality insulating materials and precise manufacturing processes to ensure signal integrity and electrical performance, suitable for high-frequency applications.

3.Technical Parameters

| Number of layers | 2 layers |

| Material | Polyimide (PI) |

| Thickness | 0.3MM |

| Surface treatment | immersion gold + gold finger 30 wheat. |

| Copper thickness | 0.5OZ |

4.Structure

Double-sided high temperature resistant flexible gold finger PCB usually consists of the following parts:

Flexible substrate: such as polyimide (PI), providing good flexibility and high temperature resistance.

Double-sided circuit layer: Arrange circuits on both sides to support the installation of a variety of electronic components.

Gold finger part: Gold fingers are designed on the edge of the PCB for connection and plugging, usually gold-plated to improve conductivity and wear resistance.

5.Application Areas

Consumer electronics: such as smartphones, tablets and wearable devices.

Industrial equipment: used for sensors and controllers in high temperature environments.

Automotive electronics: suitable for connectors and control modules inside cars.

Communication equipment: such as connection parts in routers and switches.

|

|

6.Conclusion

Double-sided high temperature resistant flexible gold finger PCB has become an indispensable component in modern electronic devices due to its excellent high temperature resistance, flexibility and reliable connectivity. As the demand for miniaturization and high performance of electronic products continues to increase, the application of this type of PCB will continue to expand, providing more efficient and reliable solutions for various industries.

FAQ

Q: First, the flexible part is easy to break.

A: When making, glue is applied at the soft and hard connection to solidify.

Q: The thermal expansion coefficient is inconsistent. The soft and hard materials will produce stress after being heated, causing the board to deform or crack.

A: When designing, special attention should be paid to using materials with the same or similar thermal expansion coefficients to reduce the problems caused by this mismatch.

Q: Do you produce the entire process of hard-soft boards by yourself?

A: Yes.

Q: Can you make HDI hard-soft boards?

A: Yes, we can make 18-layer 6-order hard-soft boards.

Q: Is your hard-soft board delivery fast?

A: Generally, the delivery time for ordinary samples is 2 weeks after EQ confirmation and 3 weeks for HDI.

8-Layer High-level Mechanical Arm System Dedicated Rigid-flex PCB

8-Layer High-level Mechanical Arm System Dedicated Rigid-flex PCB

8-Layer ENIG Smartwatch-Specific Rigid-Flex PCB

8-Layer ENIG Smartwatch-Specific Rigid-Flex PCB

6-Layer Soft-Hard Combined PCB for Electronic Scanners

6-Layer Soft-Hard Combined PCB for Electronic Scanners

6-Layer Soft-Hard Combined PCB for Electronic Educational Toys

6-Layer Soft-Hard Combined PCB for Electronic Educational Toys

3-Layer Dual Switch Rigid-Flex PCB

3-Layer Dual Switch Rigid-Flex PCB

6-Layer Flex-Rigid Industrial Drive Arm Connects PCB

6-Layer Flex-Rigid Industrial Drive Arm Connects PCB