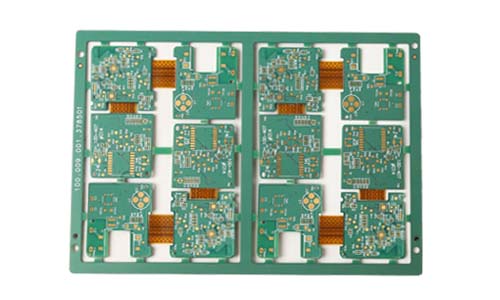

The six-layer second-order rigid-flex board is a high-performance circuit board that combines the advantages of flexible circuit boards (FPC) and rigid circuit boards (RPCB).

Six-layer Second-order Rigid-flex PCB Product Introduction

|

|

1.Product Overview

The six-layer second-order rigid-flex board is a high-performance circuit board that combines the advantages of flexible circuit boards (FPC) and rigid circuit boards (RPCB). It is designed to meet the needs of modern electronic devices for miniaturization, high density and high reliability. Such circuit boards are widely used in smart phones, tablets, wearable devices, automotive electronics and medical equipment.

2.Product Features

Multi-layer structure:

The six-layer design provides sufficient wiring space for the circuit, supports complex circuits and high-density connections, and meets the needs of multi-functional integration.

Second-order design:

The second-order structure is adopted. The combination of the flexible part and the rigid part can effectively adapt to complex shapes and space requirements, and improve the flexibility and applicability of the product.

Excellent signal integrity:

The multi-layer layout reduces signal interference and delay, ensures the stable transmission of high-frequency signals, and improves the overall performance of the device.

Excellent thermal management:

The heat dissipation characteristics are taken into consideration in the design, effectively dissipating heat and maintaining the stability of the circuit board under high load.

Vibration resistance and durability:

The combination of hard and soft design makes the circuit board have good vibration and impact resistance in various environments, suitable for demanding application scenarios.

Simplified wiring and assembly:

The use of a two-order structure helps to reduce wiring complexity, improve manufacturing efficiency, reduce production costs, and facilitate subsequent assembly.

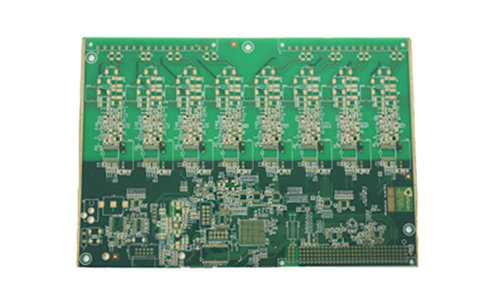

3.Technical Parameters

| Number of layers | 6 layers | Operating voltage | typically 3.3V/5V |

| Material | FR-4 (rigid part) and polyimide (flexible part) | Temperature range | -40°C to 85°C |

| Thickness | 1.6mm (rigid part), the flexible part can be customized according to needs | Surface treatment | immersion gold |

| Minimum line width/spacing | typically 0.05mm | / | / |

4.Application Areas

Smartphones and tablets: used to connect various sensors, displays and power modules to meet the needs of multi-functional integration.

Wearable devices: such as smart watches and health monitoring devices, requiring miniaturization and high integration.

Automotive electronics: used for in-vehicle navigation, entertainment systems and ADAS (Advanced Driver Assistance System) to improve safety and reliability.

Medical equipment: in high-precision medical instruments, ensure accurate signal transmission and equipment stability.

|

|

5.Conclusion

The six-layer second-order hard-soft board has become an indispensable component of modern electronic products with its excellent performance, flexible design and high-density connection capabilities. It can meet the stringent requirements of various industries for miniaturization, high performance and high reliability. We are committed to providing customers with high-quality PCB products and excellent services to help customers succeed in the fierce market competition.

FAQ

Q: The flexible part is easy to break?

A: When making, glue is applied to the connection between soft and hard to solidify.

Q:The thermal expansion coefficient is inconsistent. The soft and hard materials will generate stress after being heated, causing the board to deform or crack?

A: When designing, special attention should be paid to using materials with the same or similar thermal expansion coefficients to reduce the problems caused by this mismatch.

Q: Do you produce the entire process of hard-soft boards by yourself?

A: Yes.

Q: Can you make hard-soft boards for HDI?

A: Yes, we can make 18-layer 6-order hard-soft boards.

Q: Is your hard-soft board delivery fast?

A: Generally, the delivery time for ordinary samples is 2 weeks after EQ confirmation and 3 weeks for HDI.

8-Layer High-level Mechanical Arm System Dedicated Rigid-flex PCB

8-Layer High-level Mechanical Arm System Dedicated Rigid-flex PCB

8-Layer ENIG Smartwatch-Specific Rigid-Flex PCB

8-Layer ENIG Smartwatch-Specific Rigid-Flex PCB

6-Layer Soft-Hard Combined PCB for Electronic Scanners

6-Layer Soft-Hard Combined PCB for Electronic Scanners

6-Layer Soft-Hard Combined PCB for Electronic Educational Toys

6-Layer Soft-Hard Combined PCB for Electronic Educational Toys

3-Layer Dual Switch Rigid-Flex PCB

3-Layer Dual Switch Rigid-Flex PCB

6-Layer Flex-Rigid Industrial Drive Arm Connects PCB

6-Layer Flex-Rigid Industrial Drive Arm Connects PCB