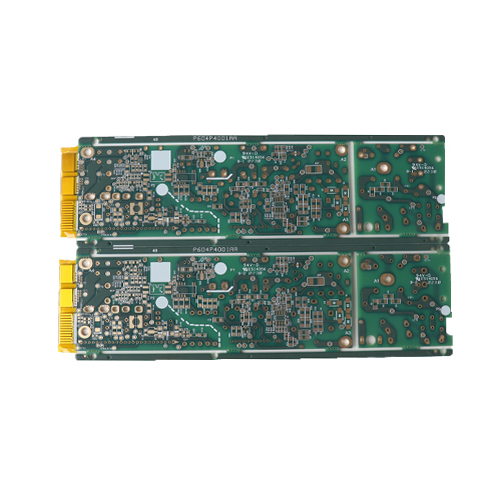

10-layer automotive thick copper coil PCB board is a high-performance printed circuit board designed for automotive electronic applications.

1. Product Overview

10-layer automotive thick copper coil PCB board is a high-performance printed circuit board designed for automotive electronic applications. The product adopts multi-layer structure and thick copper technology to meet the strict requirements of the automotive industry for high power, high reliability and environmental resistance. It is widely used in electric vehicles, autonomous driving systems and on-board electronic equipment.

|

|

2.Main Features

10-layer design:

Adopt 10-layer PCB structure to provide higher wiring density and better signal integrity.

Effectively reduce signal interference and crosstalk, and improve overall performance.

Thick copper technology:

Copper thickness is usually 3oz (about 105μm) or higher, suitable for high current applications.

Provide better heat dissipation performance to meet the needs of high-power electronic equipment.

High temperature and environmental resistance:

Adopt high temperature resistant materials to ensure stability in the automotive working environment.

With good moisture resistance, shock resistance and chemical corrosion resistance, it can adapt to various harsh environments.

Excellent electrical performance:

Design supports high-speed signal transmission, suitable for on-board communication and control systems.

Use proper impedance control and differential signal design to ensure signal integrity.

Multiple surface treatments:

Provide multiple surface treatment options such as ENIG, HASL, OSP, etc. to meet different customer needs.

Adapt to different welding processes and environmental requirements.

3.Technical Specifications

| Number of layers | 10 layers | Ink color | green oil and white characters |

| Material | FR-4, SY1000-2 | Half-hole process | 4.0MM |

| Thickness | 5.0mm | Dielectric constant | between 4.0 and 4.5 |

| Copper thickness | 5 inner layers and 5 outer layers | Surface treatment | ENIG |

4.Application Areas

Electric vehicles: used in battery management systems, charging modules and electric drive systems.

Autonomous driving: used in sensors, control units and communication modules.

In-vehicle electronics: suitable for infotainment systems, navigation systems and in-vehicle controllers.

Safety systems: used in key safety components such as automotive airbags and ABS systems.

|

|

5.Conclusion

The 10-layer automotive thick copper coil PCB board is a high-performance, reliable product designed to meet the needs of modern automotive electronic equipment for high power and high-density wiring. Its advanced thick copper technology and excellent electrical performance make it an ideal choice for the automotive industry, providing stable support for various on-board electronic equipment.

FAQ

1.Q: What files are used in PCB production?

A: PCB production requires Gerber files and PCB manufacturing specifications, such as the required substrate material, finished thickness, copper layer thickness, solder mask color, and design layout requirements.

2.Q: When can I get a quotation after I provide Gerber, product process requirements?

A: Our sales staff will give you a quotation within 1 hour.

3.Q: How to solve the copper foil blistering issue in automotive PCB production?

A: Copper foil blistering issues may be due to uneven plating or incomplete cleaning, and can be avoided by improving plating and cleaning processes.

4.Q: Which automotive manufacturers have you cooperated with?

A: Honda, Toyota, BYD, etc.