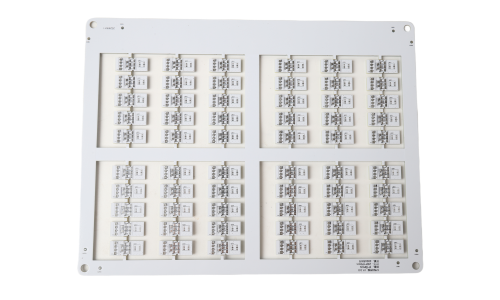

The four-layer automotive control PCB (Printed Circuit Board) circuit board is a high-performance circuit board designed for automotive electronic systems.

Four-layer Automotive Control PCB Circuit Board Product Introduction

|

|

1. Product Overview

The four-layer automotive control PCB (Printed Circuit Board) circuit board is a high-performance circuit board designed for automotive electronic systems. It adopts a four-layer structure with higher signal integrity, anti-interference ability and thermal management performance, and is suitable for various automotive electronic control units (ECUs), such as engine control, body control, infotainment systems, etc.

2.Product Features

High-density design:

The four-layer structure provides more wiring space, supports the layout of high-density components, and adapts to the needs of modern automobiles for miniaturization of electronic systems.

Superior signal integrity:

The multi-layer design effectively reduces signal interference and crosstalk, ensuring the stability of high-speed signal transmission.

Good heat dissipation performance:

The multi-layer design can better disperse heat and extend the service life of circuit boards and components, especially suitable for high-power automotive control applications.

High reliability:

The material selection meets automotive industry standards (such as AEC-Q100) to ensure stable operation in harsh environments (such as high temperature, humidity and vibration).

Good electromagnetic compatibility (EMC):

Optimized stacking design and grounding layout reduce electromagnetic interference and meet the EMC standards of automotive electronics.

Multiple surface treatment technologies:

Provide a variety of surface treatment options, such as HASL, ENIG, OSP, etc., to meet the needs of different customers.

3. Application Areas

Engine control unit (ECU): to achieve engine performance optimization and emission control.

Body control module: including lighting control, window control and safety system, etc.

Infotainment system: supports audio and video processing, navigation and car networking functions.

Battery management system (BMS): monitors and manages the battery status of electric vehicles.

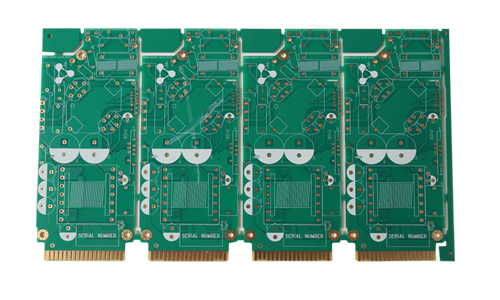

4. Technical Specifications

| Number of layers | 4 | Minimum line width and line spacing | 0.3/0.3MM |

| Board thickness | 1.6mm | Minimum aperture | 0.3 |

| Board material | S1141 | Surface treatment | lead-free tin spraying |

| Copper thickness | 2OZ for inner and outer layers | Process points | IPC III standard |

5. Production Process

1. Design verification: Use professional PCB design software for circuit design and simulation.

2. Material procurement: Select high-quality raw materials that meet industry standards.

3. PCB manufacturing: After printing, etching, drilling, copper plating and other processes, the manufacturing of circuit boards is completed.

4. Assembly test: Soldering, assembly and functional testing of components are carried out to ensure product quality.

5. Quality control: Production and inspection are carried out in strict accordance with ISO9001 and other quality management systems.

|

|

6. Customer Service

Technical support: Provide design consultation and technical support to help customers optimize product design.

After-sales service: Provide comprehensive after-sales service to ensure customer satisfaction.

7. Summary

The four-layer automotive control PCB circuit board has become an indispensable and important part of modern automotive electronic systems due to its superior performance and reliability. We are committed to providing customers with high-quality products and services to help the automotive industry's intelligent and electrified process.

FAQ

1.Q: How many employees do you have in your factory?

A: More than 500.

2.Q: How far is your factory from the nearest airport?

A: About 30 kilometers.

3.Q: How to solve the warpage issue in automotive PCB production?

A: Warping issues are typically related to uneven substrate stress and can be improved by optimizing the stacking structure and thermal treatment processes.

4.Q: Can you provide samples?

A: We have the capability to quickly prototype PCBs and offer comprehensive technical support.