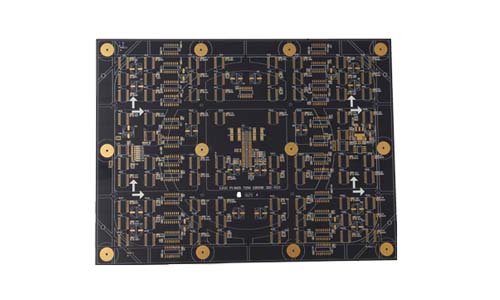

Four-layer inner and outer layers 2OZ copper thick PCB circuit board is a high-performance, high-reliability multi-layer circuit board, which is widely used in communication equipment, power modules, automotive electronics, industrial control and other fields.

Four-Layer Inner And Outer Layers 2OZ Copper Thick PCB Circuit Board Product Introduction

Four-layer inner and outer layers 2OZ copper thick PCB circuit board is a high-performance, high-reliability multi-layer circuit board, which is widely used in communication equipment, power modules, automotive electronics, industrial control and other fields. This PCB circuit board provides higher current carrying capacity and heat dissipation performance through four-layer design and 2OZ copper thickness, meeting the needs of high-power and high-density circuits. The following is a detailed introduction to the four-layer inner and outer layers 2OZ copper thick PCB circuit board product.

|

|

1.Product Overview

The four-layer inner and outer layers 2OZ copper thick PCB circuit board adopts a four-layer structure design, and the inner and outer layers are both 2OZ copper thick, which can realize complex circuit wiring in a limited space. This PCB circuit board has excellent conductivity and heat dissipation performance, and can operate stably in harsh environments such as high temperature, high humidity and high vibration, ensuring the reliability and life of electronic equipment.

2. Product Features

2.1 High Reliability

The use of high-quality substrates and advanced manufacturing processes ensures the reliability of PCBs in harsh environments such as high temperature, high humidity and high vibration.

2.2 Excellent heat dissipation performance

Through the 2OZ copper thickness design, the heat dissipation capacity of the PCB is significantly improved to meet the needs of high-power circuits.

2.3 High conductivity

The 2OZ copper thickness can provide better conductivity, reduce the resistance of the circuit board, and improve the overall performance of the system.

2.4 High anti-interference ability

Through reasonable circuit design and shielding technology, the anti-electromagnetic interference ability of the PCB is improved to ensure the stability and accuracy of signal transmission.

2.5 High integration

The four-layer design can achieve higher circuit integration, reduce the complexity and volume of the system, and improve the overall performance and reliability of the system.

3. Technical Specifications

| Base material | FR4, high TG materials, etc. | Board material | S1141 |

| Copper foil thickness | 2OZ (inner and outer layers) | Copper thickness | 2OZ for inner and outer layers |

| Number of layers | 4 | Minimum line width and line spacing | 0.3/0.3MM |

| Board thickness | 1.6mm | Minimum aperture | 0.3 |

| Surface treatment | lead-free tin spraying | Process points | IPC III standard |

4. Application Field

4.1 Communication Equipment

Used for circuit control and signal transmission of communication equipment, providing high reliability and high performance circuit solutions.

4.2 Power module

Used for circuit control and power transmission of power module, ensuring efficient power conversion and stable output.

4.3 Automotive electronics

Used for circuit control and signal transmission of automotive electronic systems, providing high reliability and long life electronic solutions.

4.4 Industrial control

Used for circuit control and signal transmission of industrial control systems, ensuring system stability and reliability.

4.5 Other high power circuits

Used for circuit control and signal transmission of other high power circuits, such as LED drivers, power tools, etc.

5. Manufacturing Process

5.1 Circuit design

Use EDA tools to design and route circuits to ensure the rationality and reliability of the circuit.

5.2 Material selection

Select high-quality substrates and copper foils to ensure the performance and reliability of the PCB.

5.3 Etching

Etch to form circuit patterns.

5.4 Vias

Drill holes and perform electroplating to form vias.

5.5 Lamination

Laminate four layers of copper foil with the substrate to form a four-layer PCB.

5.6 Surface treatment

Perform surface treatment such as HASL, ENIG, etc. to improve the welding performance and corrosion resistance of the PCB.

5.7 Welding

Weld components to complete assembly.

5.8 Testing

Perform electrical and functional tests to ensure product quality.

6. Quality Control

6.1 Raw material inspection

Ensure that the quality of the substrate and copper foil meets the standards.

6.2 Manufacturing process control

Strictly control each process to ensure product consistency and reliability.

6.3 Finished product testing

Electrical performance test, functional test and environmental test are carried out to ensure that the product meets the design requirements.

|

|

7. Conclusion

Four-layer inner and outer layer 2OZ copper thick PCB circuit board is widely used in various high-power and high-density circuits due to its high reliability, excellent heat dissipation performance and high conductivity. Through reasonable design and strict manufacturing process, efficient and reliable circuit solutions can be achieved to meet the diverse needs of electronic systems.

I hope this product introduction will be helpful to you!

FAQ

1.Q: How far is your factory from the nearest airport?

A: About 30 kilometers.

2.Q: What is your minimum order quantity?

A: One piece is enough to place an order.

3.Q: How to solve the copper foil blistering issue in automotive PCB production?

A: Copper foil blistering issues may be due to uneven plating or incomplete cleaning, and can be avoided by improving plating and cleaning processes.

4.Q: Can you provide samples?

A: We have the capability to quickly prototype PCBs and offer comprehensive technical support.