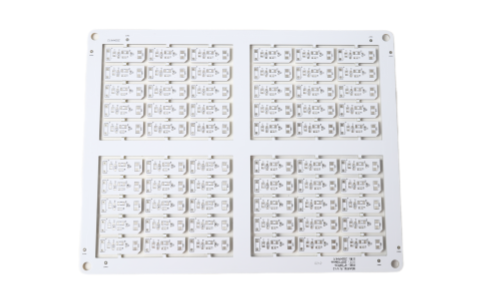

Double-sided car door PCB circuit board is a high-performance circuit board designed for car door control system, which is widely used in the field of automotive electronics, especially door control module, window lifter, door lock and safety system.

Double-sided Car Door PCB Product Introduction

|

|

1.Product Overview

Double-sided car door PCB circuit board is a high-performance circuit board designed for car door control system, which is widely used in the field of automotive electronics, especially door control module, window lifter, door lock and safety system. This circuit board combines reliability, durability and high performance to meet the strict requirements of modern automobiles for electronic control systems.

2.Product Features

Double-sided design:

Double-sided PCB design makes circuit wiring more flexible, can realize complex circuit connection in a limited space, and provide higher functional integration.

High temperature and moisture resistance:

Made of high temperature and moisture-proof materials, it can work stably under extreme temperature and humidity conditions and adapt to the stringent requirements of the automotive environment.

Excellent signal integrity:

Precise interlayer isolation and optimized signal path design ensure stable transmission of high-frequency signals, reduce interference and improve system reliability.

Anti-vibration and anti-shock ability:

The design meets the automotive industry standards and has good anti-vibration and anti-shock performance to ensure the stability and safety of the circuit board during driving.

Simplified assembly process:

Surface mount technology (SMT) and through-hole technology (THT) are used to make the assembly process more efficient and reduce production costs.

Multiple surface treatments:

Provide multiple surface treatment options, such as HASL (hot air leveling), immersion gold, OSP (organic anti-oxidation treatment), etc. to meet the needs of different customers.

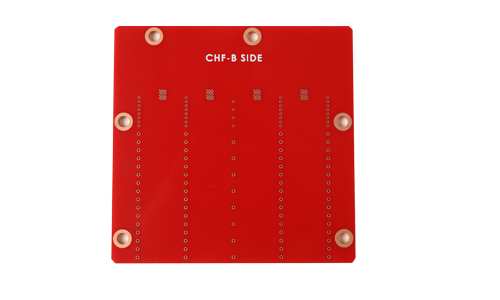

3.Technical Parameters

| Number of layers | 2 | Minimum line width and line spacing | 0.2/0.2MM |

| Board thickness | 1.6mm | Minimum aperture | 0.3 |

| Board | s1141 | Surface treatment | lead-free tin spraying |

| Copper thickness |

1OZ |

Process points | IPC III standard |

4.Application Areas

Door control module: used to control the opening, closing, locking and unlocking functions of the door.

Electric window lifter: manages the lifting and lowering operation of the window to enhance the convenience of passengers.

Door safety system: integrated with the vehicle safety system to provide safety alarm and monitoring functions.

Rearview mirror adjustment system: used for electric control of adjusting rearview mirrors.

|

|

5.Conclusion

Double-sided car door PCB circuit board has become an indispensable component in modern automotive electronic systems due to its excellent performance, reliable durability and flexible design. It can meet the strict requirements of the automotive industry for high integration, high reliability and high performance. We are committed to providing customers with high-quality PCB products and services, and promoting the continuous innovation and development of the automotive electronics industry.

FAQ

1.Q: What is your minimum order quantity?

A: One piece is enough to place an order.

2.Q: What files are used in PCB production?

A: PCB production requires Gerber files and PCB manufacturing specifications, such as the required substrate material, finished thickness, copper layer thickness, solder mask color, and design layout requirements.

3.Q: How to control the resistance of a coil power board?

A: During the circuit production process, we use industry-leading equipment to ensure that the thickness and width of each coil are balanced. Finally, we use a resistance tester for comprehensive testing to ensure that there are no issues with the resistance of each circuit board before shipping.

4.Q: Can you manufacture HDI printed circuit board substrates?

A: We can manufacture any interconnect PCB from four-layer, one-layer to 18-layer HDI.